The Stacked Beam. One beam piece on top of another, or make that three for a friggin' sandwich! The Stack beam idea is something that really only became prominent in the 2002 competition at Madison.

UF,

Sac State,

Clemson,

Penn State (more like a truss than a stack, they also repeated the Stack in 2005) all went for extra depth to achieve a better efficiency. You could also see

Southern Illinois U. Carbondale go after it in 2001, where they took home 1st in aesthetics Nationally. UF should've finished 1st in 2002, but had some difficulties with the site, as did

UW Mad, who also should've won that year,

NDSU proved to be very efficient, and didn't have any major problems with the Rules.

The key to making a Stack work is the connections. You have to get complete rigidity between stack piece to stack piece. All web members most be connected solidly if the thing will behave like it should, otherwise you're just wasting material.

UF's stack of 2002 demonstrates the best Stack technique in the history of the competition. It was top loaded, meaning everything went down in the beam, rather than middle loaded like Penn State's was in 2005 or

SIUC's was in 2001. By being top loaded connections are much simpler because you rely on the direction of load to tighten up your connection surface. When you get middle loaded you rely on your connections to transfer up to the top stack half.

Also, of note the

University of Alaska, Fairbanks, stack of 2002, it didn't win at regionals, probably because of construction, but it was beautiful, and was a National quality bridge that would've been good to show off. Anybody for UAF got pictures from that year? Send 'em in or give a link to where they are. Thanks.

UF's top loaded stack:

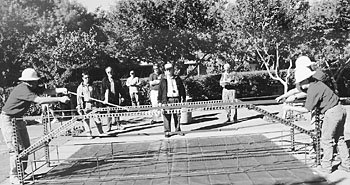

A look at UF's 2002 Pier setup, a fine piece of bolt consolidation:

SIUC of 2001 ("middle loaded"):

Penn State 2002 (top loaded) and 2005 (middle loaded, more like bottom though) respectively:

Sac State 2002 (note the lack of truss/beam transfer on the way down at points):

Clemson Tigers 2002 (then defending National Champs):

Another Clemson connection masterpiece, folks who were there at Madison might remember the 6' drill extension that got a lot of notice from the UW Mad camera crew and the judges, rules change baby!:

If you try a stack, fabrication will be a pain (if you're trying to do it correctly), set up a huge jig, and keep tolerances on connections minimal. You'll need a total connection philosophy to make it stiff, so not skimp on connections or it won't behave as planned. Go as deep as possible, trusses will kill stacks for efficiency in most cases.

2004 - Best Stack Finish is owned by Oklahoma State, see how they did it right, in a structural efficiency year too. Every connection bolted for total structure behaviour. Put a dove there instead?