Tests and Projects beating you down? That's okay, we'll procrastinate with a design session Friday night and a full day of Chrome Ollie stuff on Saturday!!!

Okay, so, here is the earth, I mean...We'll be meeting Friday night at Matt's place on Brandywine to discuss the options we have to analyze on Saturday. Our priliminary analyses show what are the likely best cases for all bridges. Friday night we will finalize all design features for each bridge that WILL be made for each design. So, for instance, if one bridge has a shallow deck, it will have a wide lateral truss, if it has a deep deck, it may have a tri-lateral truss, or we may put more DK to DK laterals in it (separate members). Either way, these decisions need to be made so we can get a dead nuts accuracy on what features will be fabricated for each bridge. Most importantly, we'll talk about constructability of each design.

On Saturday we will of course be moving our gear down to the fabrication level below the Loft so the construction boys can have their way with the wall and the staircase. This will only improve productivity. We will make brand new models from up to date DXF's in SAP, and analyze our previously recorded best results for each bridge. Right now there are 6 main designs (including a new one we haven't analyzed just yet) we are going through, each has 2 flange variations, so that makes 12 models we'll have to make from scratch on Saturday. Be ready to get into it, we may have to assign 2 bridges per person.

Matt will be in charge of making the DXF's. Team members, especially returners, will be responsible for making decisions on what will go into each design. Everyone will be responsible for analysis on Saturday. Let's be methodical and cold, and get it done with a numbing efficiency. We need clear numbers for each bridge so we can DECIDE.

After analysis, Phil and Matt, and anybody who wants to join in, will be TIGging model bridges out of steel. Each model will be approx. 2 feet long so we can get an idea of how everything looks in 3D (i.e. structural behaviour, assembly etc.). Should be fun. Phil and Matt will coordinate getting more steel to fabricate the models, which will consist of making a simple CAD model, getting dimensions and sizes set, cutting, grinding, and TIG welding the suckers together.

Okay, that's it, get ready to put forth one final analytical effort. ANY NEW DESIGNS ARE WELCOME, IF YOU HAVE AN IDEA, DON'T BE SHY.

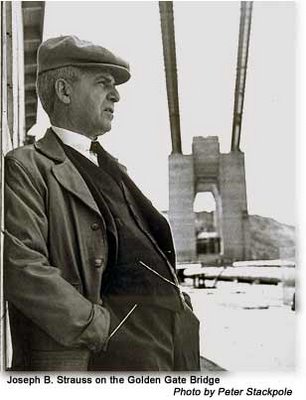

It takes a vision to start something wonderful...

It takes a vision to start something wonderful...

No comments:

Post a Comment