Monday, July 31, 2006

The cheese

To get the cheese takes the right cow. To get the right cow you have to breed, grow and nurture to perfection. This is not too unlike a Steel Bridge season -- just without the cow and cheese.

Saturday, July 29, 2006

Stack it!

The Stacked Beam. One beam piece on top of another, or make that three for a friggin' sandwich! The Stack beam idea is something that really only became prominent in the 2002 competition at Madison. UF, Sac State, Clemson, Penn State (more like a truss than a stack, they also repeated the Stack in 2005) all went for extra depth to achieve a better efficiency. You could also see Southern Illinois U. Carbondale go after it in 2001, where they took home 1st in aesthetics Nationally. UF should've finished 1st in 2002, but had some difficulties with the site, as did UW Mad, who also should've won that year, NDSU proved to be very efficient, and didn't have any major problems with the Rules.

The key to making a Stack work is the connections. You have to get complete rigidity between stack piece to stack piece. All web members most be connected solidly if the thing will behave like it should, otherwise you're just wasting material.

UF's stack of 2002 demonstrates the best Stack technique in the history of the competition. It was top loaded, meaning everything went down in the beam, rather than middle loaded like Penn State's was in 2005 or SIUC's was in 2001. By being top loaded connections are much simpler because you rely on the direction of load to tighten up your connection surface. When you get middle loaded you rely on your connections to transfer up to the top stack half.

Also, of note the University of Alaska, Fairbanks, stack of 2002, it didn't win at regionals, probably because of construction, but it was beautiful, and was a National quality bridge that would've been good to show off. Anybody for UAF got pictures from that year? Send 'em in or give a link to where they are. Thanks.

UF's top loaded stack:

A look at UF's 2002 Pier setup, a fine piece of bolt consolidation:

SIUC of 2001 ("middle loaded"):

SIUC of 2001 ("middle loaded"):

Penn State 2002 (top loaded) and 2005 (middle loaded, more like bottom though) respectively:

Sac State 2002 (note the lack of truss/beam transfer on the way down at points):

Sac State 2002 (note the lack of truss/beam transfer on the way down at points):

Clemson Tigers 2002 (then defending National Champs):

Clemson Tigers 2002 (then defending National Champs):

Another Clemson connection masterpiece, folks who were there at Madison might remember the 6' drill extension that got a lot of notice from the UW Mad camera crew and the judges, rules change baby!:

Another Clemson connection masterpiece, folks who were there at Madison might remember the 6' drill extension that got a lot of notice from the UW Mad camera crew and the judges, rules change baby!: If you try a stack, fabrication will be a pain (if you're trying to do it correctly), set up a huge jig, and keep tolerances on connections minimal. You'll need a total connection philosophy to make it stiff, so not skimp on connections or it won't behave as planned. Go as deep as possible, trusses will kill stacks for efficiency in most cases.

If you try a stack, fabrication will be a pain (if you're trying to do it correctly), set up a huge jig, and keep tolerances on connections minimal. You'll need a total connection philosophy to make it stiff, so not skimp on connections or it won't behave as planned. Go as deep as possible, trusses will kill stacks for efficiency in most cases.

2004 - Best Stack Finish is owned by Oklahoma State, see how they did it right, in a structural efficiency year too. Every connection bolted for total structure behaviour. Put a dove there instead?

The key to making a Stack work is the connections. You have to get complete rigidity between stack piece to stack piece. All web members most be connected solidly if the thing will behave like it should, otherwise you're just wasting material.

UF's stack of 2002 demonstrates the best Stack technique in the history of the competition. It was top loaded, meaning everything went down in the beam, rather than middle loaded like Penn State's was in 2005 or SIUC's was in 2001. By being top loaded connections are much simpler because you rely on the direction of load to tighten up your connection surface. When you get middle loaded you rely on your connections to transfer up to the top stack half.

Also, of note the University of Alaska, Fairbanks, stack of 2002, it didn't win at regionals, probably because of construction, but it was beautiful, and was a National quality bridge that would've been good to show off. Anybody for UAF got pictures from that year? Send 'em in or give a link to where they are. Thanks.

UF's top loaded stack:

A look at UF's 2002 Pier setup, a fine piece of bolt consolidation:

SIUC of 2001 ("middle loaded"):

SIUC of 2001 ("middle loaded"):

Penn State 2002 (top loaded) and 2005 (middle loaded, more like bottom though) respectively:

Sac State 2002 (note the lack of truss/beam transfer on the way down at points):

Sac State 2002 (note the lack of truss/beam transfer on the way down at points): Clemson Tigers 2002 (then defending National Champs):

Clemson Tigers 2002 (then defending National Champs): Another Clemson connection masterpiece, folks who were there at Madison might remember the 6' drill extension that got a lot of notice from the UW Mad camera crew and the judges, rules change baby!:

Another Clemson connection masterpiece, folks who were there at Madison might remember the 6' drill extension that got a lot of notice from the UW Mad camera crew and the judges, rules change baby!: If you try a stack, fabrication will be a pain (if you're trying to do it correctly), set up a huge jig, and keep tolerances on connections minimal. You'll need a total connection philosophy to make it stiff, so not skimp on connections or it won't behave as planned. Go as deep as possible, trusses will kill stacks for efficiency in most cases.

If you try a stack, fabrication will be a pain (if you're trying to do it correctly), set up a huge jig, and keep tolerances on connections minimal. You'll need a total connection philosophy to make it stiff, so not skimp on connections or it won't behave as planned. Go as deep as possible, trusses will kill stacks for efficiency in most cases.2004 - Best Stack Finish is owned by Oklahoma State, see how they did it right, in a structural efficiency year too. Every connection bolted for total structure behaviour. Put a dove there instead?

Friday, July 28, 2006

Ninja - Make it light, travel fast...

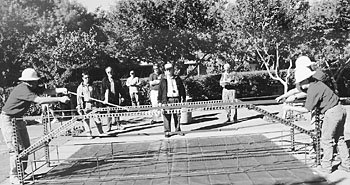

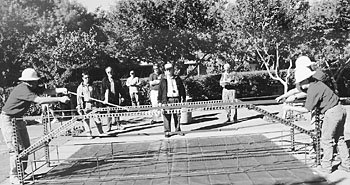

In honor of the need for weight monitoring and the need for constructability, here are some retro pics from the 2001 NSSBC in Clemson, South Carolina.

Some went deep and light, some went as shallow as possible. There was a depth factor in structural scoring, so going shallow proved to be beneficial...which is why the home team won at 5.5" depth - Chico however, a bit more with their truss, but at 101 lbs (100 lb comp. min.) they took that award home - Break out the Finite Element Analysis for that sucker, or just make it and test it eh? UF finished second - also shallow, and a construction sequence that was both simple and exciting - some real creativity on their design, and a great paint job -- 2nd place overall 2001.

How light can you go? 120 lbs? 150 lbs? At 19 feet of span, too light (w/o 7' depth) may hurt more that you think -- gotta keep it stable too, no buckling allowed!

Chico State 2001:

Clemson Tigers - 2001 NSSBC Host and Champs, note the low depth, the double 2x1 tube beam design, and the deflection flexibles on their end cantilevers - a lot of team's incorporated this backwards deflection relative bending to trick the gauges - it has since been eliminated more or less. Structural Mechanics are essential to accurately predict steel behavior under load, thus the inspired Innovation Award for their dual span beam in 2004 -- cheesy award from the judging committee, to make up an award, invite them to Nats under agreement, then DQ them, harsh...the um...TIG wire for a tool was pretty rough though - but sometimes you have to just go for it. Big Brass to Clemson in 2K4. Some Teams try to win the competition, some try to win and aim to get the Rules rewritten because of their creative thinking.

UF in 2001, extremely simple, stiff, shallow, heavy, good looking bridge.

UF in 2001, extremely simple, stiff, shallow, heavy, good looking bridge.

WTF? Ah the good ole' days where you got 4' on the member. Those are some crazy cantilevers.

Some went deep and light, some went as shallow as possible. There was a depth factor in structural scoring, so going shallow proved to be beneficial...which is why the home team won at 5.5" depth - Chico however, a bit more with their truss, but at 101 lbs (100 lb comp. min.) they took that award home - Break out the Finite Element Analysis for that sucker, or just make it and test it eh? UF finished second - also shallow, and a construction sequence that was both simple and exciting - some real creativity on their design, and a great paint job -- 2nd place overall 2001.

How light can you go? 120 lbs? 150 lbs? At 19 feet of span, too light (w/o 7' depth) may hurt more that you think -- gotta keep it stable too, no buckling allowed!

Chico State 2001:

Clemson Tigers - 2001 NSSBC Host and Champs, note the low depth, the double 2x1 tube beam design, and the deflection flexibles on their end cantilevers - a lot of team's incorporated this backwards deflection relative bending to trick the gauges - it has since been eliminated more or less. Structural Mechanics are essential to accurately predict steel behavior under load, thus the inspired Innovation Award for their dual span beam in 2004 -- cheesy award from the judging committee, to make up an award, invite them to Nats under agreement, then DQ them, harsh...the um...TIG wire for a tool was pretty rough though - but sometimes you have to just go for it. Big Brass to Clemson in 2K4. Some Teams try to win the competition, some try to win and aim to get the Rules rewritten because of their creative thinking.

UF in 2001, extremely simple, stiff, shallow, heavy, good looking bridge.

UF in 2001, extremely simple, stiff, shallow, heavy, good looking bridge.

WTF? Ah the good ole' days where you got 4' on the member. Those are some crazy cantilevers.

Thursday, July 27, 2006

Goin' Deep

The hardest thing about doing analysis for a Bridge Design, is the old principle of not falling into "Paralysis by Overanalysis". All of you reading this (most likely not too many), take these words to heart: If you are creative, build it well, and practice hard, you will be successful. The best analyzed designs don't win, it's the most determined and detail oriented Team's that win.

UF - 2005 (above) - Width in Chord members means better rotational resistance, means better stability, means better stiffness, means better efficiency.

UF - 2005 (above) - Width in Chord members means better rotational resistance, means better stability, means better stiffness, means better efficiency.

NDSU - 2004 (above) - By cutting the 15'-6" span off "near-pier" with their overtruss, The Bison were able to cut their truss members to 5 and keep their efficiency. This is probably not advisable for single span bridges ala 2005-2007, but for the dual span and corresponding 2K4 loading, it was a good idea. Note also the light/deep deck sections, and "battered" steel piers for stability during construction and rotational/frictional foundation resistance during load.

Michigan - 2004 (above) - Again, cuttin off the span for the 5 member overtruss. A different deck philosophy than NDSU (who finished 1st overall 2004, Go Blue! finished 2nd...after taking the 2003 championship ;-), the steel is located on the top side, which between chords sees less tension and more compression under load, though both flanges are essentially in tension. Michigan was far less deep than NDSU over their long span, though with their 4 person crew (UC Davis did not witness -- we were eating lunch arggghhhhh!) they managed to maintain both economy and efficiency, narrowly being beat out by the Bison, and coming as close as Chico State in 1999-2000 (2nd, 1st respectively). Michigan Champs in 2003, 2nd in 2004, good stuff donde estaban en el ano dos mil y seis Universidad de Michigan? Mas libre que no?

UF - 2005 (above) - Width in Chord members means better rotational resistance, means better stability, means better stiffness, means better efficiency.

UF - 2005 (above) - Width in Chord members means better rotational resistance, means better stability, means better stiffness, means better efficiency.

NDSU - 2004 (above) - By cutting the 15'-6" span off "near-pier" with their overtruss, The Bison were able to cut their truss members to 5 and keep their efficiency. This is probably not advisable for single span bridges ala 2005-2007, but for the dual span and corresponding 2K4 loading, it was a good idea. Note also the light/deep deck sections, and "battered" steel piers for stability during construction and rotational/frictional foundation resistance during load.

Michigan - 2004 (above) - Again, cuttin off the span for the 5 member overtruss. A different deck philosophy than NDSU (who finished 1st overall 2004, Go Blue! finished 2nd...after taking the 2003 championship ;-), the steel is located on the top side, which between chords sees less tension and more compression under load, though both flanges are essentially in tension. Michigan was far less deep than NDSU over their long span, though with their 4 person crew (UC Davis did not witness -- we were eating lunch arggghhhhh!) they managed to maintain both economy and efficiency, narrowly being beat out by the Bison, and coming as close as Chico State in 1999-2000 (2nd, 1st respectively). Michigan Champs in 2003, 2nd in 2004, good stuff donde estaban en el ano dos mil y seis Universidad de Michigan? Mas libre que no?

Tuesday, July 25, 2006

What it's all about.

Why do we all do this? The recruitment, the speeches, the explanations for why someone should be on the Team, the conceptual design, the analysis, the Team meetings with pizza and possibly beer if the Team's an older one, the material selection, the steel ordering, the de-greasing, the cutting, the miling, the lathing (is that a word?), the grinding, the welding, the attention to fabrication detail, the connection tolerances, the construction planning, the practice, the practice, the practice, THE PRACTICE, the aesthetics prep, the nervousness for only ONE day of competition, maybe two if you're good enough, the "Euphoria" of victory, the agony of defeat...be it not being prepared, bad luck or simply being out-designed/competed, the trips to Nats, the picture taking of all the other schools, the talking to all the other schools, the quiet walk bys of the Team members from other schools you know to be as good, if not, better than you are, the last day practices, the final competition, the award banquets, the rewards or the "get 'em next year's...

Why Why Why? Because it's fun, because you're addicted, because you want to impress your future employer, because engineers have to have each other or they really don't have anybody, because of school pride, because you live in the middle of nowhere, because you want to do something with your life, because of the friendships, because of the parties, because of the thrill of victory, because of the things you learn, because you know it's worth it, IF ONLY FOR A TRIP TO CALI BABY!

2006

2005

2004

2003

2003

2002

2002

2001

2001

2000

2000

Can you name all these champions?

Can you name all these champions?

We compete and strive to be the best in the United States, Mexico, Puerto Rico, Canada and Japan -- be the best, work for your awards. That's why we do this...

...Until German schools enter, then we're all screwed.

Thanks for the tip Tigers:

definitely da bomb.

definitely da bomb.

Why Why Why? Because it's fun, because you're addicted, because you want to impress your future employer, because engineers have to have each other or they really don't have anybody, because of school pride, because you live in the middle of nowhere, because you want to do something with your life, because of the friendships, because of the parties, because of the thrill of victory, because of the things you learn, because you know it's worth it, IF ONLY FOR A TRIP TO CALI BABY!

2006

2005

2004

2003

2003 2002

2002 2001

2001 2000

2000 Can you name all these champions?

Can you name all these champions?We compete and strive to be the best in the United States, Mexico, Puerto Rico, Canada and Japan -- be the best, work for your awards. That's why we do this...

...Until German schools enter, then we're all screwed.

Thanks for the tip Tigers:

definitely da bomb.

definitely da bomb.

Monday, July 24, 2006

Monday, Monday...

Yes it is Monday. We analyzed two new bridge design concepts, one showed obvious structural advantages to the simple beam, but how stiff can we really get it? Who knows for sure, time to dial in the predictions.

Go deep or go fast that has always been the question, but with this scoring system it may as well be all the same category. We'll have to set priorities.

Here's the Ecole de Technologie Superieure (ETS) super balance tool, the pic sucks but this slanted pier stood with no holding at all. Is this legal THIS year? Clarification please, everybody likes doing this and now we may not be able to do it, friggin' rules changes, hafta think now.

Go deep or go fast that has always been the question, but with this scoring system it may as well be all the same category. We'll have to set priorities.

Here's the Ecole de Technologie Superieure (ETS) super balance tool, the pic sucks but this slanted pier stood with no holding at all. Is this legal THIS year? Clarification please, everybody likes doing this and now we may not be able to do it, friggin' rules changes, hafta think now.

Sunday, July 23, 2006

New Rules (not from Bill Maher)

What up Bridge Bums?

The Rules came out last Thursday, 7/20 -- Matt found them at about 1 in the morning, said he couldn't sleep, but it sounds more like a Shyamalanian connection to everybody else.

A lot of changes, and a return to the "sqaureness" of the competition. NO more skew, but there are some interesting construction changes. As for the structure, it's a bit more varied, like canoe of sorts, bridges could theoretically be as short as 18' or as long as 21'. So the challenge to keep the span minimal while simultaneously not getting the piers too close for comfort will be an interesting concept.

Lots of temporary piers for most folks probably, not only are they allowed to go everywhere on the site, but the supporting constructed portions by builders is pretty much forbidden. Only a 9 foot river, but this will leave some issues for those who choose a truss and desire central chords which will need to be reached.

Beams are also a possibility - the loading proves that no killer central load could let the beam sneak through.

Time is money, weight is money. Notice how the Efficiency has been split up, so we can see weight is slightly more important than stiffness, though we don't want stiffness to skyrocket.

Good mix of necessity for this year's type selection. Should see a wide range of designs winning depending on the project management of each school Team.

As for Chrome-Ollie, you can expect a damn muy bien bridge.

The Rules came out last Thursday, 7/20 -- Matt found them at about 1 in the morning, said he couldn't sleep, but it sounds more like a Shyamalanian connection to everybody else.

A lot of changes, and a return to the "sqaureness" of the competition. NO more skew, but there are some interesting construction changes. As for the structure, it's a bit more varied, like canoe of sorts, bridges could theoretically be as short as 18' or as long as 21'. So the challenge to keep the span minimal while simultaneously not getting the piers too close for comfort will be an interesting concept.

Lots of temporary piers for most folks probably, not only are they allowed to go everywhere on the site, but the supporting constructed portions by builders is pretty much forbidden. Only a 9 foot river, but this will leave some issues for those who choose a truss and desire central chords which will need to be reached.

Beams are also a possibility - the loading proves that no killer central load could let the beam sneak through.

Time is money, weight is money. Notice how the Efficiency has been split up, so we can see weight is slightly more important than stiffness, though we don't want stiffness to skyrocket.

Good mix of necessity for this year's type selection. Should see a wide range of designs winning depending on the project management of each school Team.

As for Chrome-Ollie, you can expect a damn muy bien bridge.

Saturday, July 22, 2006

tester

nothing new, just testing. the blog chromeollie.blogspot.com is messing up, this one will be the new one until the other one gets sorted out...

chromeollie07....

chromeollie07....

Subscribe to:

Comments (Atom)